Electri-Flex Company: Global Leader in Flexible Electrical Conduits

Electri-Flex has over 60 years of success manufacturing the highest-quality flexible liquid-tight conduit in the world.

Founded in 1955, Electri-Flex has perfected the design and manufacture of its line of over 50 flexible electrical conduits. A true innovator in the liquid-tight conduit industry.

Making the best product does not create success, without sales, service and marketing programmes that meet the needs of our customers. Our partners can expect outstanding service from fast shipments on in-stock items, as well as developing a conduit for unique applications. Our team of salesmen, customer-service agents and applications engineers can assist at every stage of the buying process.

We’re a Family

The Company was founded by Harold Kinander, Snr, and continues its success through being owned and operated by the third generation of the Kinander family. Within the Electri-Flex organisation is a tightly-knit extended family of employees working together to carry out the Company’s mission. The cultural focus is on quality products and services, together with a strong sense of loyalty to the Company and its partners.

Our International Partners

Electri-Flex Company partners with the leaders in their markets and most of them have been a part of the Electri-Flex family for many years. Our partners are located worldwide and are hand-selected based on demonstrated high standards of commitment and performance.

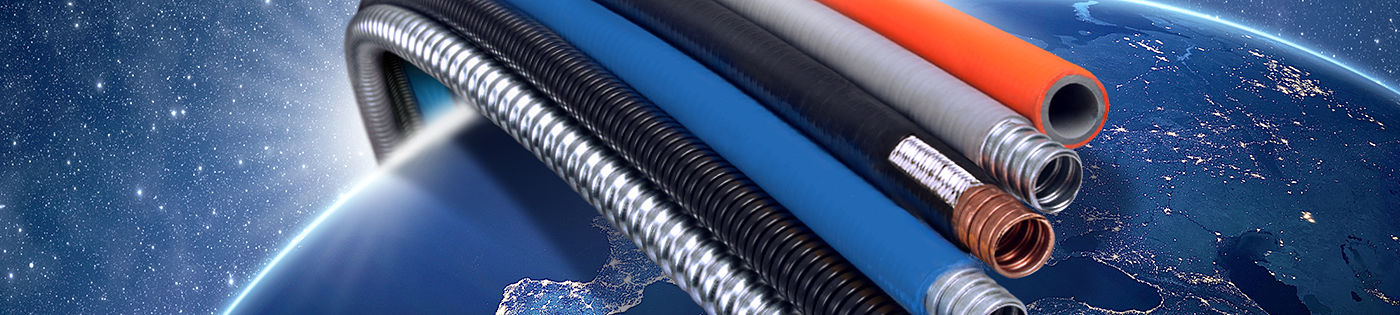

Diversification within One Product Line: Liquatite®

Electri-Flex Company is the world’s leading manufacturer of the most diverse line of flexible electrical conduits in respect to sizes, types, and colours. The Liquatite® line includes over 50 varieties of electrical conduits for contractors, OEMs, industrial maintenance and repair (MRO), government, utility and export users. Product categories include:

- Jacketed Metallic: Offers a liquid-tight flexible sealed raceway with the strength of a metal core. Conduits range from CE-Certified, UL-listed and CSA-certified products to specialised ones designed for extreme temperatures, non-halogen, low smoke, RFI shielding and food grade applications.

- Non-Jacketed Metallic: Often referred to as “Greenfield” or “Reduced Wall Flex,” they are free of non-metallic materials and offer the highest physical protection for electrical wiring. Products offer a flexible raceway with tight bends, high impact and crush strength and UL and CSA certifications.

- Non-Metallic: Made without a metal core and are ideal for corrosive environments, high flexing applications and where weight might be an issue. Materials used are flexible and rigid PVC. Products offer sunlight resistance, suitability for use in extreme temperatures, and UL and CSA certifications.

- EMI/RFI Shielded: Shield-Flex® conduits offer three levels of shielding effectiveness and are used to protect sensitive electronic circuits used in communications, radar and data transmission from electromagnetic and radio frequency interference (EMI/RFI). Shield-Flex is also available with a halogen-free jacketing.

- Nylon: The Corrlok® System is composed of four types of flexible corrugated-nylon conduits and is designed for a wide range of applications. Corrlok provides a very lightweight, liquid-tight, flexible raceway that’s easy to work with and stands up to tough environments. The corrugated-nylon conduit comes with compatible connectors which are available with NPT, metric or PG threads.

- Fittings: This significant offering of fittings provides a choice for all types of flexible electrical conduits. A true quality solution that maintains integrity throughout the system.

All Liquatite® products are manufactured in Roselle, Illinois, U.S.A. The majority of production tools and methods used in the manufacture of liquid-tight conduits by the Company are unique in that they were developed and built by Electri-Flex in its own Tool Shop. Custom design and manufacturing capabilities are also available.

Superior Construction and Quality

Our years of applications experience have taught us how to distinguish a superior flexible electrical liquid-tight conduit from a less desirable one. As a result, we have developed design methods for our conduit that help prevent common problems. Our unique construction includes:

- More convolutions per foot than other conduit—meaning more steel per foot for greater crush strength.

- Advanced Quality Control—ensuring precise I.D./O.D. tolerances for a superior liquid-tight connexion.

- Patented Flexi-bond for non-sleeving, non-wrinkling jacket—improves performance and appearance and prevents unravelling.

- Squarelocked and Interlocked inner metallic strip—provides added mechanical strength.

Our vertically-integrated manufacturing system gives us complete quality control over every step of the conduit production process, from raw-materials processing through assembly. Testing is performed by a team of Quality Assurance experts at each production stage. Every foot of conduit is tested for proper dimensional characteristics utilising the latest measuring devices.