How to Install Electrical Conduit Faster & More Efficiently

When it comes to electrical conduit installation, labor is often the most significant cost—and the hardest to predict.

The key to controlling it?

Smarter planning, better material choices and installation methods designed for speed.

By switching to flexible conduit systems such as LFMC, liquidtight conduit and flexible metal conduit, contractors can streamline installation, reduce crew fatigue and keep their projects on schedule.

Here’s how to install electrical conduit more efficiently while maintaining code compliance and long-term reliability, whether you’re outfitting a new commercial space or retrofitting a complex mechanical room.

Plan with Precision to Prevent Delays

Every successful conduit installation starts with detailed preparation. Reviewing blueprints early, conducting a site walk, and confirming material availability before work begins can prevent costly delays.

Coordination with other trades—especially plumbing, HVAC and fire suppression—also reduces the risk of routing conflicts or blocked access points.

Measurement of accuracy is equally essential.

Poor layout planning leads to material waste and expensive rework. Even a few inches of error can necessitate rerouting or lead to over-ordering. Tools like laser distance meters, chalk lines and digital construction planning apps—such as PlanGrid, Fieldwire or BIM software—can help crews pre-map conduit paths with efficiency.

Use Flexible Conduit to Cut Labor Time

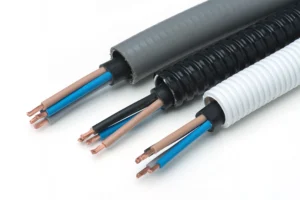

Flexible Conduit

Unlike rigid conduit, flex conduit doesn’t require precise bending, threading or alignment. Installers can quickly route around corners, structural elements or existing systems without specialized tools. That flexibility reduces both tool time and physical strain.

Products like liquidtight flexible metal conduit (LFMC) are ideal for demanding environments, including rooftops, washdown areas, and outdoor applications. They’re also well-suited for retrofits and other tight spaces where traditional rigid conduit would be cumbersome or time-consuming to install.

By eliminating the need for elbow fittings and conduit bodies, liquidtight conduit with a tight bend radius simplifies installations and reduces the number of connectors, supports, and materials required. This solution also minimizes the risk of error and accelerates the inspection process.

Pre-Cutting and Prefab Save Serious Time

Time spent working overhead or in tight spaces is the most exhausting—and expensive—part of conduit installation.

That’s why staging conduit cuts before installation can significantly boost productivity and reduce worker fatigue.

handheld hacksaw

Instead of cutting conduit piece by piece in the ceiling, crews can use a jobsite table or prefab area to cut flexible metal conduit in advance. For clean, square cuts—especially on steel-core conduit—use a handheld hacksaw with the proper blade or a band saw with a no-set blade. Do not use reciprocating saws, which can leave jagged edges, crush conduit and pose safety risks.

Bandsaw

Once cut properly, each piece can be labeled according to the layout plan, turning the install phase into a streamlined plug-and-play task.

Prefabricated conduit assemblies are especially effective on large or repetitive projects such as electrical rooms, school wings or commercial kitchens. Pre-cut lengths with factory-installed boxes or cable pulls can eliminate hours of labor per floor, while also reducing error and clutter.

For best practices, see Electri-Flex’s guides on cutting flexible conduit and handling techniques. For added efficiency, explore their custom cutting and packaging services.

Selecting the Right Conduit for the Job

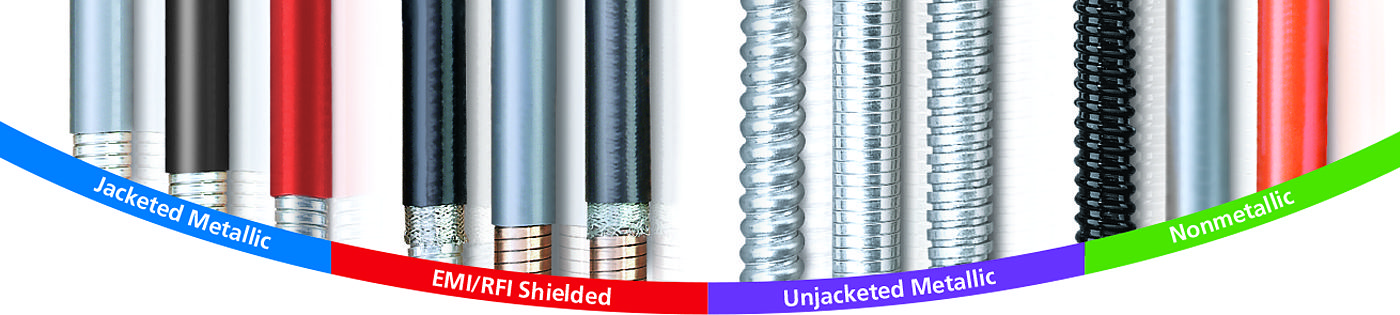

Choosing the appropriate conduit for your environment is crucial—especially when it comes to long-term performance, compliance and efficiency. Electri-Flex offers a wide range of flexible conduit solutions tailored to various challenges.

For basic commercial interior installations, Type NM (non-metallic) is a lightweight and easy-to-install option. In wet, oily or outdoor locations, Type LT (liquidtight flexible metal conduit) provides added protection with a durable thermoplastic jacket.

Type LAFG is a food-grade conduit certified to NSF standards, making it ideal for use in food and beverage facilities or pharmaceutical plants.

If your application involves high heat, chemical exposure, or UV, Electri-Flex also offers high-temperature conduit, corrosion-resistant conduit and sunlight-resistant flexible conduit.

Safety environments, such as hospitals, subways or airports, may require low-smoke conduit, which reduces toxic gas emissions during a fire. These conduits not only support safety but often reduce the need for additional fireproofing steps, saving time and money.

Workforce Organization and Mistake Prevention

On the jobsite, crew efficiency can make or break a schedule.

Instead of having every worker multitask, crews should be organized into focused teams—those handling layout, those cutting and staging, and those performing final installation. This lean workflow helps avoid congestion and increase output.

Common time-wasting mistakes—such as misaligned conduit supports, incorrect sizing, or overuse of fittings—can be avoided through thorough planning and regular quality checks. Always reference a conduit wire fill chart when sizing runs to ensure compliance with National Electrical Code (NEC) standards and avoid future rework.

Real-World Impact: Cutting Install Times Significantly

Many contractors report substantial time savings—sometimes up to 40%—when switching to flexible conduit on projects with complex layouts or harsh environments.

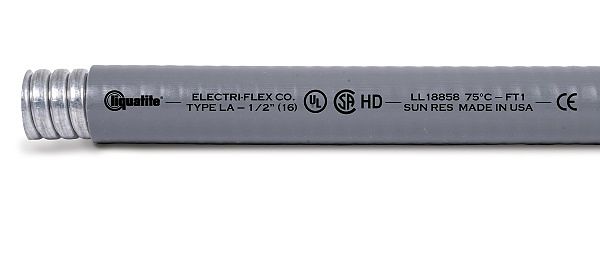

Liquatite Approved – Liquidtight Flexible Metal Conduit

Rooftop HVAC systems, for example, benefit significantly from LFMC conduit, which can be routed quickly and sealed tightly, even in weather-exposed conditions.

Compared to rigid alternatives, flexible metal conduit also reduces tool wear and installer fatigue. Its adaptability makes it a go-to choice for remodels and infrastructure upgrades where space is tight and layouts are unpredictable.

Fast, Flexible and Future-Ready

Knowing how to install electrical conduit efficiently isn’t just about tools—it’s about choosing smarter materials and implementing strategies that maximize labor.

With products like flexible metal conduit, liquidtight conduit, and corrosion-resistant flexible conduit, installers can reduce time on task, minimize physical strain, and hit project milestones more reliably.

Whether you’re wiring a distribution center, a cleanroom or a rooftop unit, flexible conduit systems offer the adaptability, speed and compliance that today’s projects demand.

For more insight into smart installation strategies and the complete line of flexible conduit solutions, including LFMC, liquidtight tight and food-grade conduit, contact Electri-Flex today.