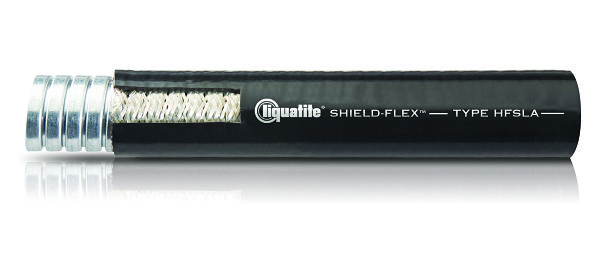

Part of the SHIELD-FLEX® family of EMI/RFI Shielding conduits, as well as Zero-Halogen product family.

Type HFSLA is identical to standard UL Listed liquidtight flexible steel conduit (See Type LA) but is augmented with a tinned copper shielding braid located over the inner steel core and under its protective Polyurethane jacket. The braid offers a minimum of 90% coverage.

Type HFSLA liquidtight flexible shielding conduit is designed for field installations where safety concerns exist regarding a material’s reaction in a fire situation. The specially formulated thermoplastic polyurethane jacket has excellent flame retardancy and low smoke characteristics. Acidic gases such as hydrogen chloride, hydrogen fluoride and hydrogen bromide are virtually eliminated as products of combustion.

Construction:

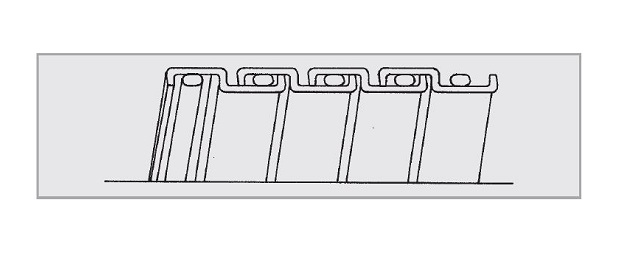

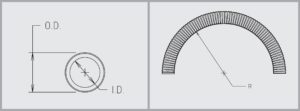

Inner Core:

- Hot Dipped Galvanized Steel

- 3/8” – 1-1/4” Squarelock Profile with continuous bonding strip

- 1-1/2” – 2” Fully Interlocked Profile

- Shielded with a tinned copper braid

Liquidtight Jacket:

- Zero Halogen Polyurethane

- Resistant to Ozone, Hydrocarbons, Moderate Chemicals and Oils

- Flame Retardant

- Low Smoke

- Low Toxicity

- Sunlight Resistant (UV)

Application:

- Meets the requirements of Bombardier SMP 800-C for Toxic Gas Generation.

- Meets the requirements of both ASTM E162 for Flame Spread and ASTM E662 for Smoke Generation.

This conduit is intended for installation in accordance with Article 350 of the NEC (ANSI/NFPA-70)

- Suitable as an equipment grounding conductor per Article 250.118(6). Larger sizes require separate grounding conductor.

- Suitable for use in hazardous locations: Class I, Div. 2 and Classes II and III.

- PVC jacket is resistant to a wide variety of oils, acids, alkaline and ultraviolet light.

- Accepts Standard Metallic Liquidtight Fittings

- Designed for wiring applications requiring shielding effectiveness from Electromagnetic and Radio Frequency Interference (EMI/RFI)

HFSLA is a trademark of Electri-Flex Company, registered in the U.S. Patent and Trademark Office.

Combustion & Flammability Properties

COMBUSTION & FLAMMABILITY |

TEST |

VALUE |

| Vertical Burn (Material) | UL94 | V-0 Rating; No Flaming Drips |

| Vertical Burn (Conduit) | UL360 | Pass; No Flaming Drips |

| Oxygen Index % | D2863 | 28.5 |

| Flame Spread Index | ASTM E162 | 25; No Flaming Drips |

| Smoke Generation (Flaming) | ASTM E662 (NFPA 258) | Ds [email protected] Min/Ds [email protected] Min |

| Smoke Generation (Non-Flaming) | ASTM E662 (NFPA 258) | Ds [email protected] Min/Ds [email protected] Min |

| Toxic Gas Generation | BOMBARDIER SMP 800-C | Pass |

| Toxicity Index | NES 713 | 3.9 |

* Test data is based on controlled laboratory conditions and does not necessarily reflect performance in actual fire conditions. Additional product information available upon request.

Markets:

Aerospace, Cell Towers, Data Centers, Defense, Healthcare, Renewable Energy, Ship Building, Telecommunications

All Products Proudly Made in the USA

All Products Proudly Made in the USA